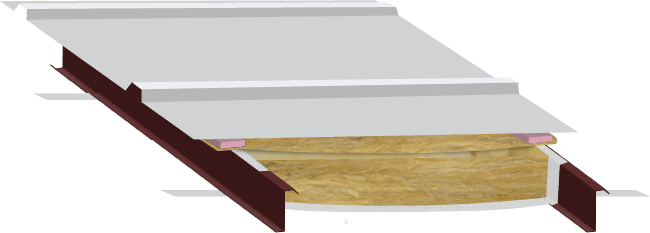

Long-Tab Banded System

Long-Tab Banded (LTB) filled-cavity insulation is a popular and cost-effective method for insulating metal building roofs and walls.

The long-tab banded system involves using laminated insulation with extra-long facing tabs as well as metal banding for support. The extra-long facing tabs can be adhered to the tops of the purlins, suspending the insulation within the cavity , while the metal banding is attached using TEK screws perpendicular to and below the purlins to help support the weight of the laminated insulation in the purlin cavity.

For roofs, faced fiberglass is installed parallel and between the purlins. Unfaced insulation is installed perpendicular and over the top of the purlins. The metal banding is secured perpendicular and to the bottom of the purlins.

For walls, when a higher R-value is desired, unfaced fiberglass can be installed perpendicular to the girts and faced fiberglass parallel to the girts.

Key Benefits

- High R-Value/Low U-Value: This system offers high thermal resistance, helping to reduce energy consumption and lower heating and cooling costs.

- Cost-Effective: It’s a relatively affordable insulation solution compared to other options.

- Easy Installation: The installation process is straightforward and can be completed efficiently.

- Flexibility: It accommodates various building configurations and allows for easy installation of electrical, HVAC, and sprinkler systems.

- IMPORTANT! The Long-Tab Banded Insulation System does NOT act as fall protection.

Long-tab banded filled-cavity insulation is a reliable and efficient choice for insulating metal buildings.