Surface Burning Characteristics Of Insulation For Metal Buildings

April 1, 2020

The January 2019 issue of Insulation Outlook featured an article by Dwayne Sloan, Director of Principal Engineers and Regulatory Services for the Building and Life Safety Technologies Division at Underwriters Laboratories (UL), entitled A Focus on Insulation Surface-Burning Characteristics . Within that article, Mr. Sloan referenced model codes and installation standards for insulation products. In this article, we will take a deeper dive into those codes, regulations and requirements as they pertain to insulation for metal buildings.

Re-Cap Of Why We Have ASTM E84 (UL723)

The ancient Greek philosopher Plato, in the dialogue Republic coined the phrase that necessity is the mother of invention .

More than 70 years ago, within a relatively short period of time, the United States experienced three tragic fires:

- November 1942, Cocoanut Grove Nightclub in Boston – 492 Deaths

- June 1946, La Salle Hotel in Chicago – 61 Deaths

- December 1946, Winecroft Hotel in Atlanta – 127 Deaths

The common theme in each of these fires was the rapid flame progression along the surfaces of the interior finish products. As a result, the necessity for a test method was invented – ASTM E84 (UL 723), a test for determining the surface burning characteristics of interior finish building materials.

Building Codes And Metal Building Insulation

ASTM E84 (UL 723) is the standard test that is referenced in all codes regarding the surface burning characteristics of insulation products. The result of the test yields two indices; a flame spread index and a smoke developed index. Code and Standard bodies now use these indices to classify various insulation products.

The International Building Code (IBC) groups products into three classes, depending on their index values. Chapter 8 Interior Finishes, Section 803.1.1 states interior wall and ceiling finish materials shall be classified in accordance with ASTM E84 (UL 723) and classified as the following:

- Class A = Flame spread index 0-25; smoke developed index 0-450

- Class B = Flame spread index 26-75; smoke developed index 0-450

- Class C = Flame spread index 76-200; smoke developed index 0-450

Armed with this knowledge, the next obvious question is how does this affect the insulation products and systems used in the construction of a metal building?

First, let’s look at where fiberglass insulation is used.

Within a metal building, fiberglass insulation is most commonly used in the walls and ceilings, and is exposed to the interior of the building. Fiberglass insulation can also be found in concealed spaces and in plenum applications. For example, insulation is sometimes left exposed within an enclosed cavity of a metal building, which serves as the return air plenum for the HVAC system.

Now that we know where it is used, what codes do we need to understand regarding the surface burning characteristics of the insulation being used?

Let’s first address plenum applications. The following codes have specific requirements regarding this:

- International Mechanical Code (IMC)

- Uniform Mechanical Code (UMC)

- National Fire Protection Agency (NFPA 90A)

All state that any insulation material exposed within a plenum must have:

- Flame Spread < 25

- Smoke-developed < 50

Next we have insulating materials in concealed spaces. This is addressed by the International Building Code (IBC), Section 720.2, stating that the insulation must be Class A:

- Flame Spread < 25

- Smoke-developed < 450

Lastly, the most common use of insulation in a metal building are for walls and ceilings, where it is exposed. The International Building Code (IBC), Section 720.3 requires all exposed insulating materials be Class A:

- Flame Spread < 25

- Smoke-developed < 450

When it comes to insulating metal building ceilings and walls, there are several system options. Per ASHRAE 90.1-2019, insulation systems can be Single Layer, Double Layer, Liner System, or Filled Cavity. In each of these systems, the insulation can be either faced (laminated) or unfaced.

In general, regarding fiberglass insulation systems within a metal building, there are 3 types of building materials that need to be Class A: Unfaced Metal Building Insulation, Vapor Retarder Facings, and Faced Metal Building Insulation.

Common Misconceptions Regarding Faced Metal Building Insulation

What everyone should understand is that there is a significant difference between ASTM E84 (UL 723) testing on “Individual” materials vs. “Composite” materials.

As we’ve already established, faced or laminated metal building insulation that will be exposed to the interior of the structure must be Class A. Therefore, the faced or laminated product is a “Composite” material and must be tested as such. What does that mean? Laminated metal building insulation is composed of fiberglass blanket, a vapor retarder facing, and some type of adhesive. If the unfaced insulation has been tested and is Class A, and the vapor retarder facing has been tested and is Class A, and the adhesive has been tested and is Class A, it DOES NOT mean that the faced metal building insulation is Class A.

The true surface burning characteristic of faced metal building insulation can only be known by testing the material when all components are together, as a finished product.

How Do I Know If The Faced Metal Building Insulation I’m Using Is Class A?

The only way to know is if the surface burning characteristics index rating is on the product label.

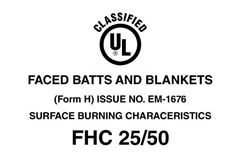

There are third party certification companies that work with manufacturers to insure that products comply with the ASTM E84 (UL 723) requirements. As an example, many manufacturers use Underwriters Laboratories for certification. Certification with UL means that a product has been tested AND is manufactured to consistently match the same parameters of the original product that was tested and complies. As an added assurance, the manufacturing facility keeps records of all production and is routinely visited and evaluated by the third party. In this case, it would be UL. As a result, a UL Classification Mark would be printed on the label, as can be seen in figure 1. The FHC 25/50 on this label refers to Fire Hazard Classification, with 25 being the flame spread index and 50 being the smoke developed in index. Therefore, the product would be Class A material.

In summary, the vast majority of fiberglass insulation systems in metal buildings should be Class A material in order to comply with building codes. The only way to be certain that the materials being used will meet building codes is if the surface burning characteristics index rating is on the product label (as in Figure 1).